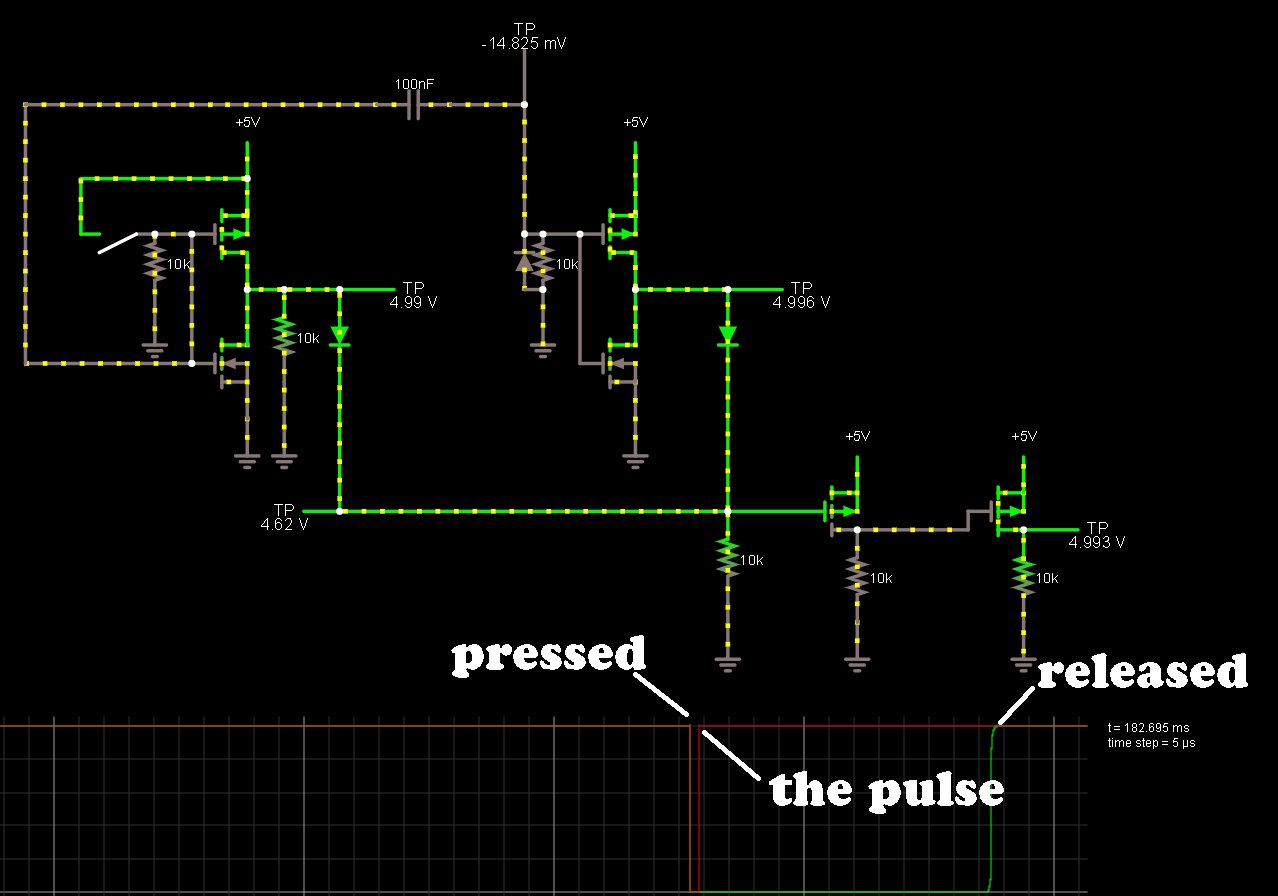

Simulation on CircuitJS: Link

Background: It might be needed to have a reset pulse with boot code to detect reset and hold

The circuit uses 4 pMOS and 2 nMOS

The idea is to use or gate and capacitor charging one pin to release the second input for the output to be a low pulse

The 2 pMOS flip on the bottom right side might not be needed, as 4.65v and 4.93v will be both counted as high, so not that important.

- PD

- Communication ( Bring IOT Router)

- No background

- Arduino \\158.132.52.176\WorkingDirectory\installfile

- UART config

- UART send OSC

import processing.core.PApplet; // need the "this" in parent app to work

import processing.serial.*;

import cc.arduino.*;

public abstract class ArduinoHandler{

public ArduinoHandler(PApplet parent){

String[] ard_list = Arduino.list();

// Find the Arduino

boolean found = false;

println("Find Arduino!");

for( int i = 0; i < ard_list.length; i++ ){

String dev_now = ard_list[i]; // get one name

println(dev_now);

if( dev_now.substring(0, ard_prefix.length()).equals(ard_prefix) ){

println("Arduino found @ "+dev_now);

m_arduino = new Arduino(parent, Arduino.list()[i], 57600);

found = true; // found the arduino

break;

}

}

// not found then notify

if(!found){

println("No arduino found, please check your connection");

}

// Do the init

if(!init()){

println("Something wrong with initilization");

}

};

protected abstract boolean init();

protected Arduino m_arduino;

// This is written for on arduino on MAC only needs other stuff after having multiple platforms

protected final String ard_prefix = "/dev/cu.usbmodem";

}

- ORID questioning strategy

- teaching students to memorize facts

- https://www.slideshare.net/shutingchuang940/orid-43587601

The acronym “ORID” is derived from the first letters of the four stages of questioning:

Objective

Reflective

Interpretative

Decision

- Old Schools produce identical "machines" , outdated

- Future jobs~ flexible

- Self learning

- Encouragement

- Equal strategy

- Everyone talks about same topic

- Progress / deeper and deeper

Problems:

- Soft filament feeding speed control , too fast will jam in the pushing gear (Need to watch it printing the whole process for now)

- Temperature, 210~220 is OK, however much easier to jam in the head and burn.

VIDEO0020.mp4 (Not playable codec, so you'll need to download)

Following version still will print with problem.

- Suggestion list

- Cut the 2d lab part from 1st Sem for Ogre and put some of Sem2's lab into Sem 1.

- Start develop the final game earlier

- Needs to do presentation right after exam week

- Technical work

- http://ogre3d.org/tikiwiki/tiki-index.php?page=Raycasting+to+the+polygon+level , need to implement a precision ray casting example

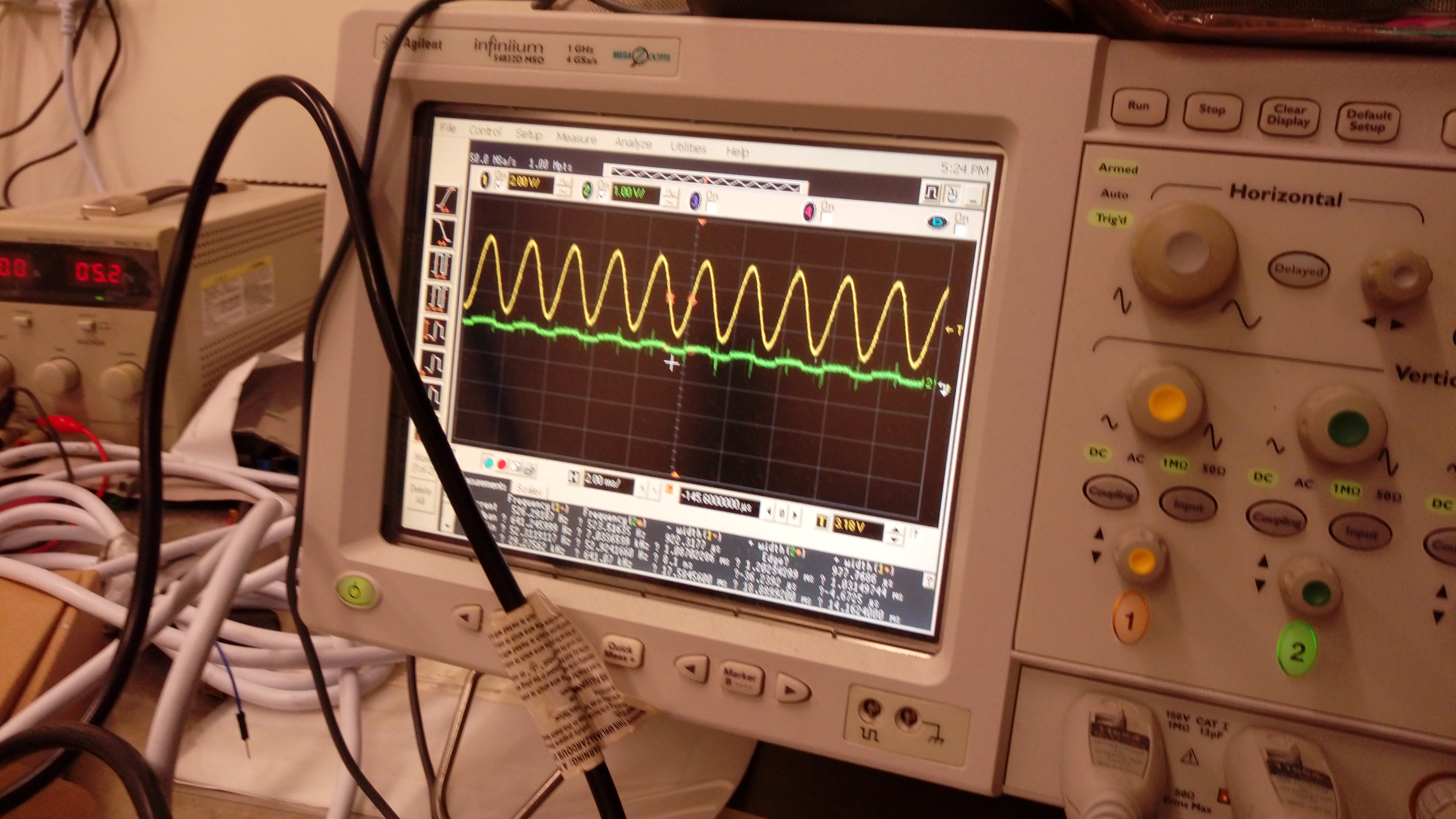

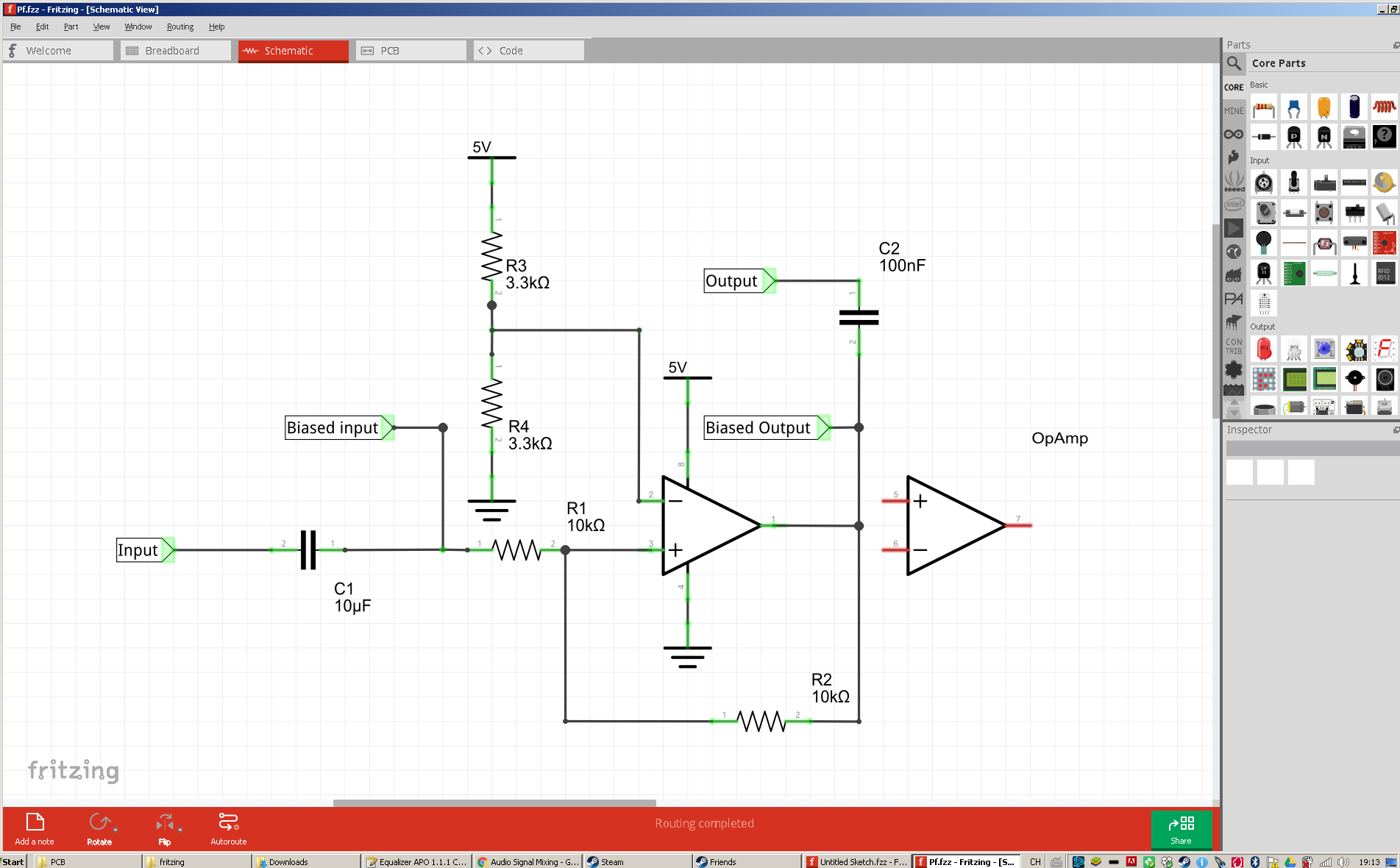

- Successfully biased the voltage to 2.5v using 2 3k3 resistors and a capacitor (106 , non polarized)

- Biasing using only 5v (2.5vpp max) is not sufficient, with any load, the output is clipped.

- Green = output , Yellow = biased input (VPP kept well)

- Positive feedback,

- Group 1

- Skin conductivity to stress (GSR analogRead)

- Noise to attract

- Toy movement(Actuation)

- Heart Rate sensor (possible)

- Chart

- Group 2

- Interactive DJ experience

- Card insert

- 8 x 8 scanning

- Group 3

- Neopixel + tap

- Pressure matt

- Group 4

- RFID

- Reflective

- No duplicated line (line that overlaps might be hazardous, more likely to catch on fire)

- Workflow for both SD and IC

- Stroke weight = 0.1px

- No colour inside any shape

- Use continuous line instead of individual sections

- Teach how to join lines in AI

- Convert to AI3 format before cutting

- For SD, it uses corelDraw for final output

- For IC, it uses DXF which is CAD/CAM format.

- Measure the total output area before cutting

- Needs to be smaller than

- The material size

- The workable area of laser cutting

- For SD it's 800mm x 450mm

- IC has bigger size but needs inquiry

- Needs to be smaller than

- For card-board, thinner is prefered (suggested by Unknown User (sdwillo))

Recognising 3D products and sourcing part documentation with scanned data

- This is entry point to an old research, no source code is found